A new regenerative brew for the UK

A new regenerative brew for the UK

Our journey towards 100% regenerative barley in the UK has begun. In 2023, CBMC contracted 23 UK farmers to grow regeneratively grown barley.

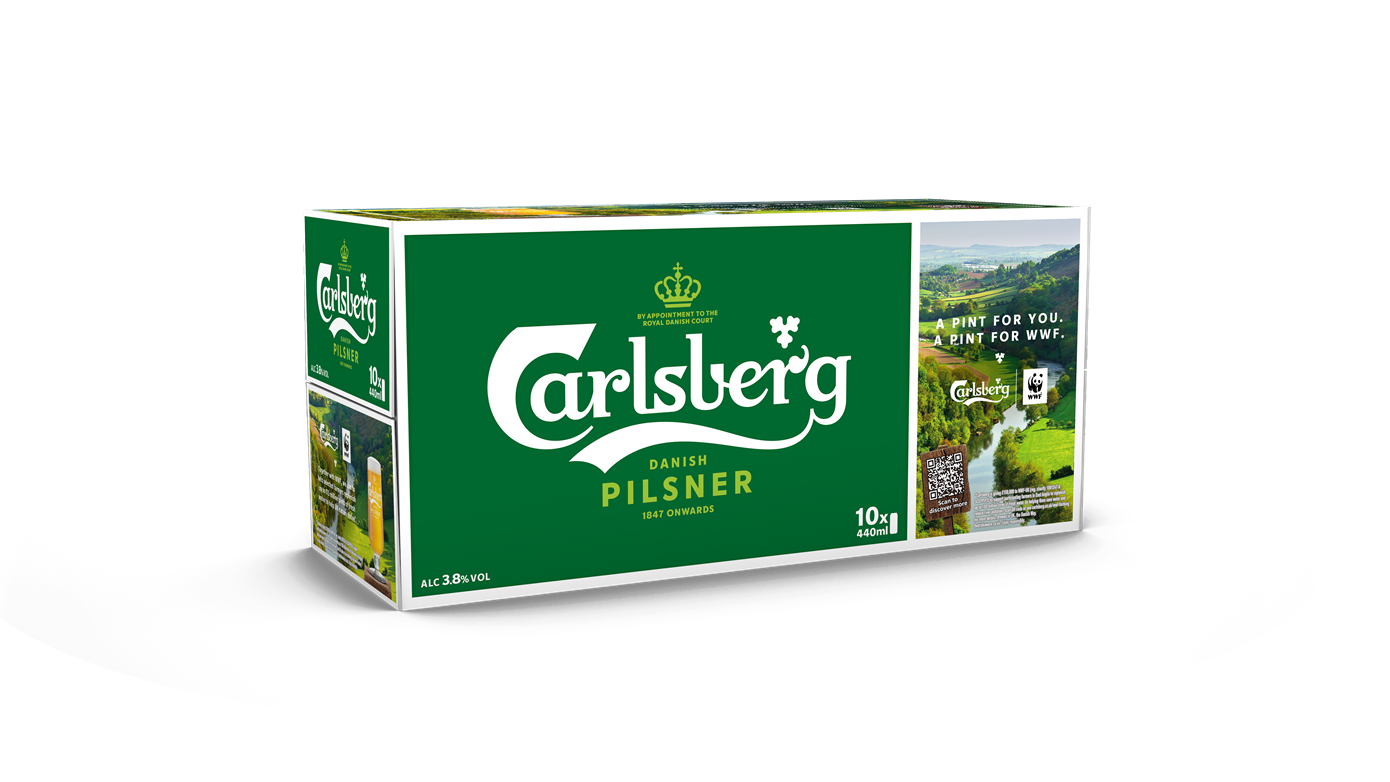

United Kingdom. In 2023, Carlsberg Marston’s Brewing Company, in close collaboration with the Archer-Daniel-Midland Company (ADM), contracted 23 UK farmers to grow regeneratively grown barley.

The harvest will be used to brew Carlsberg Danish Pilsner from 2024, and we aim to expand this pilot to source enough regenerative barley to make all our beer under this brand in the UK by 2027. Furthermore, we are committed to make our brews in the UK with 100% regenerative barley by 2031.

“At CMBC, we’re deeply committed to the future of sustainable brewing, which is why we’re excited to support British farmers in adopting regenerative techniques – preserving soil health, reducing carbon emissions, and leading the way for our sector. Our strategic partnerships are the cornerstone of this transformative journey, as we work hand in hand with local farmers, traders, maltsters, agronomists and NGOs. Together we’re not just brewing beer; we’re brewing a brighter, regenerative future for all.”

- Paul Davies, CEO, Carlsberg Marston's Brewing Company

Developed at the Carlsberg Research Laboratory

The variety of barley being grown has been developed at the Carlsberg Research Laboratory. It brings brew quality benefits and additional climate benefits by reducing the amount of energy and associated carbon emissions during the brewing process.

With this initiative we're supporting farmers in the transition to regenerative practices, including helping them to measure and track carbon emissions and soil health. Participating farmers also have opportunities to learn from each other, and to promote regenerative and replenishment techniques beyond the core groups.

ZERO Farming Footprint

Within our ZERO Farming Footprint initiative we’re working with farmers and their communities, collaborating with suppliers, investing in research and development while championing the benefits of a regenerative farming approach.

The use of regenerative farming methods will also drive further carbon reductions, as the second largest share of our carbon footprint comes from growing and processing the raw materials used in our beers.

Want to know more about our targets and how we'll achieve this?

Thirsty for more?

Helping BeerLao farm rice more sustainably

To reach our ZERO Farming Footprint goal, we are taking steps to adopt more sustainable agricultural practices.

Sourcing regenerative malt barley in Denmark

In 2024, our Danish business began sourcing a malt barley grown using regenerative principles, which will move us closer to our goal of achieving a ZERO Farming Footprint.

Regenerative farming in Finland

KOFF Christmas beer, produced at our carbon-neutral Sinebrychoff brewery, is the most popular Christmas beer in Finland. It contains a very special barley from regenerative practices.

Central & Eastern Europe and India

-

Azerbaijan

-

Belarus

-

Bulgaria

-

Canada

-

Croatia

-

Estonia

-

Greece

-

Hungary

-

India

-

Italy

-

Kazakhstan

-

Latvia

-

Lithuania

-

Serbia

-

Ukraine